A trailer is never “just a trailer.”

If you’re hauling heavy equipment, building a tiny home, or planning an ADU build, the trailer is the foundation. Literally. Get it right, and everything else works more smoothly. Get it wrong, and you’ll spend years fighting problems you didn’t need in the first place.

Custom built equipment trailers exist for one simple reason. Off-the-lot trailers are made for averages. Average loads. Average roads. Average use cases. And most serious builders don’t live in the average world.

This is where custom matters. And where Trailer Made Custom Trailers separates itself from everyone cutting corners in the back corner of a lot somewhere.

Let’s break down what features you can actually add to custom built equipment trailers, why they matter, and how they protect your investment long term.

Why Custom Built Equipment Trailers Are Worth It

The short answer is control.

When you go custom, you decide how the trailer works for your life, not the other way around. Axle placement. Frame strength. Deck height. Load ratings. All tuned to what you’re hauling and how you’re using it.

This matters even more if you’re looking at tiny home trailers for sale or planning an ADU for sale down the line. A weak or poorly designed trailer will show its flaws fast. Sagging frames. Cracks. Doors that won’t close anymore. Plumbing issues. Electrical headaches.

Truth is, most trailer failures don’t happen overnight. They happen slowly, quietly, and expensively.

An engineered trailer, built right from day one, avoids all of that.

Engineered Frames

Let’s start with the big one. The frame.

A real custom built equipment trailer starts with an engineered frame, not a guess. This means load calculations. Weight distribution analysis. Stress points are identified before the steel ever gets cut.

This is especially critical for tiny house kits and ADU builds. These structures are static loads that sit for years. They don’t flex as equipment does.

Trailer Made builds frames specifically engineered for long-term stationary loads. That’s not marketing fluff. That’s the difference between a trailer that holds its shape and one that slowly twists itself into a problem.

Cutting corners here is the fastest way to lose money. Period.

Axle Configuration You Actually Need

Axles aren’t one-size-fits-all. But plenty of manufacturers pretend they are.

Custom built equipment trailers let you choose axle count, rating, spacing, and suspension style based on your real load. Not some generic number pulled from a catalog.

Tandem axles. Triple axles. Heavy-duty torsion axles. Spring axles with reinforced hangers.

If you’re looking at tiny home trailers for sale, axle placement is everything. Get it wrong, and towing becomes sketchy. Tires wear unevenly. Bearings fail early.

Trailer Made Custom Trailers designs axle setups around the actual structure sitting on top. That’s how it should be done.

Deck Height Adjustments

Lower deck height changes everything.

Easier loading. Better stability. Lower center of gravity. Less stress on the frame.

For equipment trailers, this means smoother loading angles and safer operation. For tiny homes and ADUs, it often determines whether your build even meets height restrictions.

Custom deck height options allow you to stay compliant without compromising strength. That balance is harder than it looks, and it’s where experienced builders shine.

Reinforced Crossmembers Where It Counts

Here’s a mistake people make. They add thicker steel everywhere, thinking more steel equals a better trailer.

That’s not how engineering works.

Smart design reinforces high-stress areas with properly spaced crossmembers. It strengthens the trailer without unnecessary weight. That matters for towing, braking, and long-term durability.

Trailer Made focuses on reinforcement where it actually takes abuse. Tongue area. Axle mounts. Load points. Not random overkill.

That’s the difference between engineered strength and brute force guessing.

Custom Tongue Length and Design

Tongue length affects towing stability more than most people realize.

Too short, and the trailer sways. Too long and maneuverability suffers. Custom built equipment trailers allow you to dial this in.

You can also add reinforced tongues for heavy equipment or extended loads. Gooseneck options. Adjustable couplers. Weight distribution compatibility.

For tiny home trailers for sale, tongue design plays a role in transport permits and towing behavior. It’s not just a front-end detail. It’s a safety factor.

Integrated Tie-Down Systems

Tie-downs shouldn’t be an afterthought.

Custom trailers let you integrate D-rings, stake pockets, E-track, or custom anchor points exactly where you need them. Not where the factory decided was convenient.

This is critical for equipment transport. It’s just as important during the construction phases of tiny homes or ADUs when materials are moving on and off constantly.

Better tie-downs mean less damage, fewer headaches, and faster workdays.

Brake Systems Built for Real Weight

Electric brakes are common. Electric-over-hydraulic brakes are better for heavier loads.

Custom built equipment trailers allow you to choose the braking system that actually matches your weight and usage. Including upgraded wiring, breakaway systems, and controller compatibility.

If you’re hauling a tiny home or ADU shell, stopping power isn’t optional. It’s safety. Anyone telling you otherwise hasn’t done the math.

Wiring and Lighting That Lasts

This one gets ignored until it fails.

Cheap wiring corrodes. Lights flicker. Connections fail right when you need them most. Usually at night. Or in the rain.

Custom trailers can be wired with sealed connectors, protected runs, and heavy-duty lighting. LED systems. Marker placement that actually makes sense.

Trailer Made builds wiring to survive real use, not just pass inspection.

Suspension Options for Ride Quality

Rough roads beat up trailers. And whatever’s sitting on them.

Upgraded suspension options help protect your cargo and your investment. This matters a lot for tiny house kits and ADU builds, where interior finishes don’t appreciate vibration.

Smoother rides mean fewer cracks, fewer issues, and longer lifespan across the board.

Galvanized or Coated Steel Options

Rust is slow, but it’s relentless.

Custom-built equipment trailers can be finished with galvanization or specialty coatings to resist corrosion. Especially important if you’re in coastal areas, snowy regions, or places where road salt eats metal for breakfast.

Long-term value comes from protection. Not patch jobs later.

Modular Expansion Capabilities

Here’s something smart builders think about early. Expansion.

Custom trailers can be designed to accept future upgrades. Additional supports. Extensions. Structural reinforcements for later modifications.

If you plan to convert a trailer into an ADU for sale down the line, this flexibility matters. It protects resale value and keeps options open.

Tiny Home Trailers for Sale: Why Custom Wins

There are plenty of tiny home trailers for sale online. Most look fine. Until you look closer.

The problem is hidden compromises. Thin steel. Poor welds. Axles not rated for static loads. No engineering behind the design.

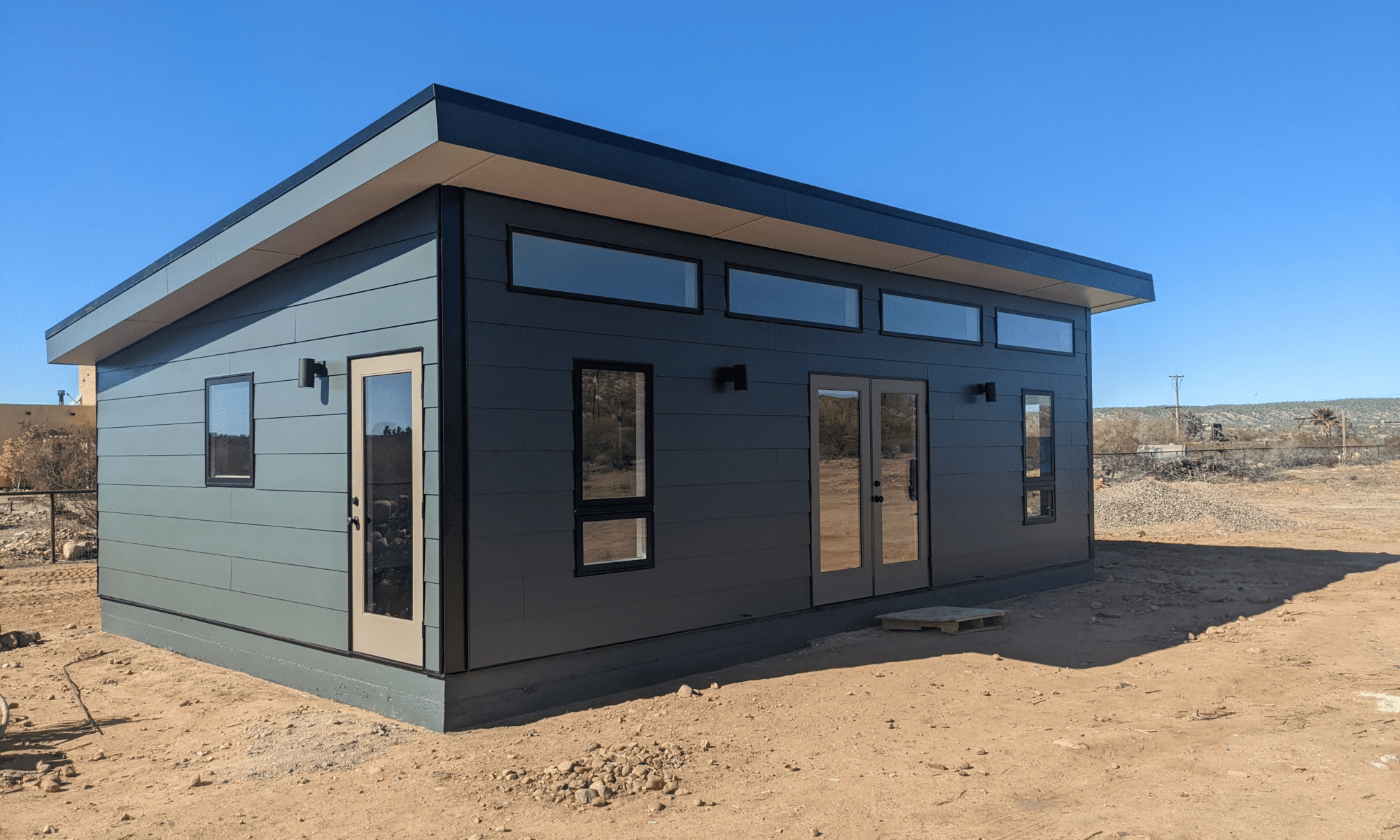

Trailer Made Custom Trailers builds tiny home trailers as foundations, not transport toys. Designed for long-term living. Engineered to support real structures.

That’s why builders who care about quality keep coming back.

ADUs, Zoning, and Trailer Design

If you’re working with an ADU builder or planning to list an ADU for sale, trailer design can impact permitting and compliance.

Height limits. Load classifications. Transport rules. These aren’t abstract concerns. They affect timelines and budgets.

Custom trailers let you design within real-world constraints, instead of trying to fix problems after steel is already welded.

Why Cutting Corners Always Costs More

This part needs to be said clearly.

Cheap trailers cost more over time.

Repairs. Reinforcement retrofits. Structural failures. Lost resale value. Safety risks.

An engineered trailer costs more upfront because it’s doing more work. It’s thinking ahead. It’s built for reality, not best-case scenarios.

Trailer Made’s approach is simple. Build it right once. Avoid fixing it forever.

Long-Term Value Over Short-Term Savings

Trailers don’t show off. They don’t get Instagram likes. But they quietly decide whether your project succeeds or struggles.

Custom-built equipment trailers protect the structure above them. That’s where the real money is.

Whether you’re hauling machinery, building tiny house kits, or working toward an ADU for sale, the trailer is the base layer of everything.

You don’t cheap out on foundations. The same rule applies here.

Why Trailer Made Custom Trailers Leads the Industry

Experience shows up in the details.

Engineered designs. Thoughtful feature integration. No shortcuts. No guesswork.

Trailer Made Custom Trailers builds with long-term use in mind. Builders, homeowners, and professionals trust them because the trailers hold up. Year after year.

That’s not hype. That’s a reputation earned the hard way.

Final Thoughts

Custom built equipment trailers aren’t about showing off. They’re about control, safety, and durability.

The right features turn a trailer into a real foundation. One that supports your work instead of creating problems.

If you’re serious about quality, long-term value, and doing things right the first time, custom isn’t optional. It’s the standard.

Visit Trailer Made Trailers to start your build

FAQs

What makes custom built equipment trailers better than standard trailers?

Custom trailers are designed around your actual load, not averages. This means better weight distribution, stronger frames, and fewer long-term problems. They’re built to last, not just to sell fast.

Are tiny home trailers for sale worth buying custom?

Yes. Tiny homes create static loads that standard trailers aren’t designed for. Custom tiny home trailers are engineered to support long-term living without sagging or structural issues.

Why are engineered trailers so important?

Engineered trailers account for stress points, load distribution, and long-term use. Without engineering, trailers rely on guesswork, which leads to failures over time.

Can custom trailers help with ADU projects?

Absolutely. Custom trailers can be designed to meet height, weight, and zoning constraints. This makes them a smart foundation for ADUs and future resale.

How do I start a custom trailer build?

Start by working with a builder who understands engineering and long-term value. Trailer Made Custom Trailers walks you through the process from design to delivery, without cutting corners.